Key Features & Benefits

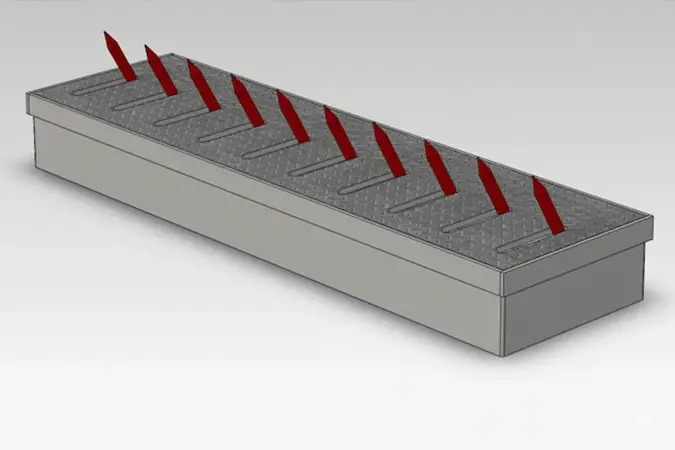

- Heavy-duty **mechanical spike** system ensuring one-way vehicle movement

- Fully mechanical operation — **no power required** for standard models

- Reinforced steel spikes puncture tyres instantly on reverse entry attempts

- Ideal for parking lots, industrial gates, logistic hubs & secured perimeters

- Low maintenance, long-life mechanical design suitable for GCC climate

- Customizable width, spike height & load capacity as per project needs

- Optional integration with boom barriers & access control systems

Benefits

- Ensures unidirectional vehicle movement and prevents reverse intrusion

- Zero electricity required → ideal for remote or low-infrastructure sites

- Long-lasting system with minimal wear and maintenance needs

- Operates smoothly even under heavy vehicle load conditions

Technical Specifications

| Parameter |

Specification |

| Barrier Type |

Mechanical Spike Barrier (One-Way Traffic Control) |

| Material |

High-Strength Steel with Anti-Corrosion Coating |

| Operation |

Fully Mechanical (Automatic Spike Retraction) |

| Spike Height |

75–150 mm (customizable) |

| Load Capacity |

Up to 20 Tons / axle (depending on model) |

| Lane Width |

2–6 meters (customizable) |

| Installation |

Surface-Mounted or In-Ground Options |

| Optional Integration |

Boom Barriers, Access Control, Sensors, Signaling Lights |

Applications

- Parking Lots & Multi-Level Car Parks

- Warehouse & Logistic Centers

- Industrial Entry & Exit Points

- Commercial & Residential Gated Communities

- Private Properties & Estate Entrances

- Low-Infrastructure Zones where electrical systems aren't feasible

Certifications / Compliance

- ISO 9001:2015 Certified Manufacturing

- Material Certified for Structural Strength & Load Testing

- Compliant with GCC Safety & Traffic Control Regulations

- Tested for long-term durability and repetitive mechanical performance

Installation & Maintenance

Mechanical Spike Barriers are easy to install and require only basic civil work and anchoring. Secure Gulf provides complete installation, alignment, and commissioning services along with on-site training. Their mechanical design ensures dependable long-term operation with minimal servicing needs.

Maintenance Checklist

- Monthly inspection of spike movement & return mechanism

- Lubrication of hinges, pivots & mechanical joints

- Cleaning debris from spike slots for smooth operation

- Quarterly inspection for structural alignment and load-bearing capacity

- Surface cleaning & anti-corrosion repainting for outdoor installations